Product Information > Electric Water Pumps

Why an electric pump?

Nearly all cars still have mechanical water pumps - which is a bit strange, as electric pumps are more efficient in terms of the power they consume, and they can also match an engine’s cooling needs much more effectively. A mechanical pump is always a compromise. Belt or camshaft driven, its pumping rate varies directly with engine speed, so that at tickover in traffic jams it will barely pump sufficient water around the system, and at high revs it will be trying to pump too much, leading to wasted power and the risk of cavitation (disrupted flow caused by the pump trying to shift more coolant than the waterways, hoses etc will take).

The latest car designs are using electrical water pumps, as their reliability, availability and superior performance become understood. But the major advantages of improved cooling and higher engine efficiency (3%-5% fuel savings), or having more power available from a freer revving engine, are already available to anyone who wants to retrofit their car with a Davies Craig electric pump. Another major benefit is the ability of an electric pump to keep running after engine shutdown, to prevent the heat soak problems to which some engines are prone.

Benefits

The main benefit

from fitting an EWP® is improved engine temperature control,

particularly where the engine has a tendency to overheat. Other major

benefits are increased efficiency from eliminating the belt driven mechanical

water pump, therefore gaining fuel savings and increased horsepower. It is

possible to gain an increase of up to 13hp of extra power by removing the

mechanical pump. The engine power used by the mechanical pump increases as the

cube of its speed – so when the mechanical pump speed doubles from idle speed

say; 600rpm to 1200 rpm, the power it takes increases by eight times. Then

another eight times going to 2400 rpm, and so on up to maximum engine speed. It

is this extra power and torque that is released by deleting the mechanical pump

that provides the fuel savings that is estimated to be 3.5% to 10%.

Other advantages will include lower emissions by virtue

of faster engine warm up, better engine temperature

management, eliminating engine heat soak and improved engine

life. Another advantage is the weight reduction, a typical mechanical pump

weighs between 3kg and 5kg, where as the EWP’s are between 0.9kg and 1.15kg

depending on flow rate.

The Davies Craig Range

The Davies Craig family of eight pump sizes (EBP23, EBP25, EBP40, EWP80, EWP115, EWP130, EWP140 and EWP150) is suitable for a very wide range of applications. We sell them for:

• Cars with tuned engines

• Racing cars

• Older cars with thermosyphon-cooled engines

• Classic cars with less than adequate cooling

• Cars with a worn or broken mechanical water

pump

• Kit cars

The pumps are also suited to a range of non-car applications:

• Motorcyles and Trikes

• Hovercraft

• Commercial vehicles

• Go karts

• Boats, caravans and motorhomes

• Even solar heating systems!

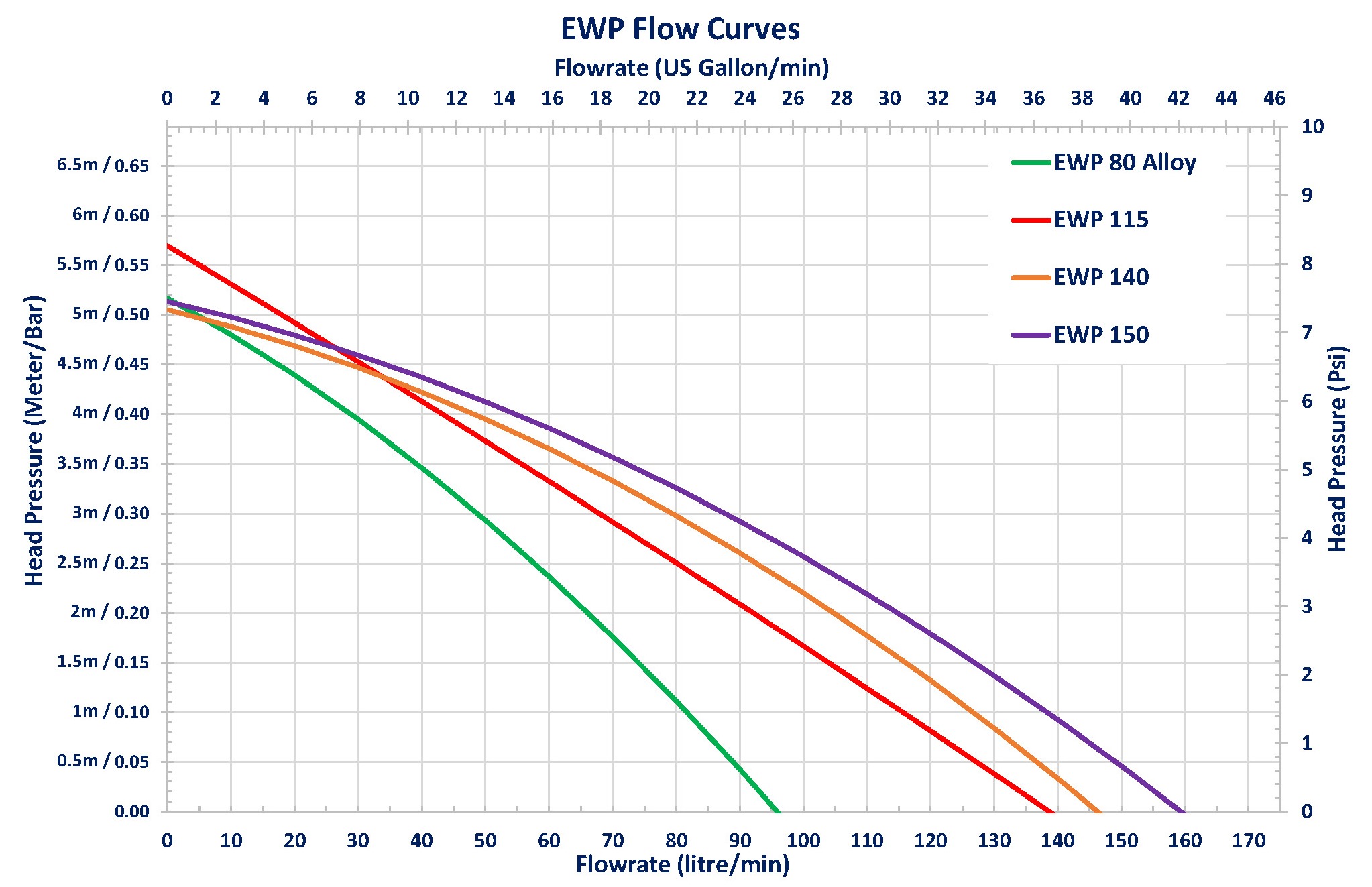

Electric Water Pump Comparison chart

EWP80 Nylon & Alloy Most small and medium sized car engines, up to around 2.5 litres/200HP. The EWP80 is the most flexible pump in terms of mounting configurations. It is now available in alloy with either fixed or flanged inlet and outlet, alongside the original nylon flanged inlet/outlet pump.

EWP115 For higher power and tuned engines in the 200-350HP range. Available with either glass-filled nylon or alloy body. The performance of the two pumps is identical, but the alloy pump can be hard mounted and so is more suitable for rough treatment eg in rally cars.

EEWP130/EWP140 Suitable for most engines up to around 400bhp, particularly where space is tight, as it shares the EWP80’s flexibility in mounting configurations.

EWP150 Suits very high powered engines, race cars, very hard-working 4x4s, many commercial vehicles etc. All EWP150s have alloy bodies.

Pump

Control

There are two ways to control an electric water pump - with

either an on/off switch, or with a speed controller.

If the electric pump is being used to assist an existing mechanical pump and provide extra coolant flow when the old pump can’t keep up, then a thermatic switch is the right control choice. These switches monitor coolant temperature and switch the pump on when the needle starts to rise above normal, just like the operation of an electric fan. Switches - Read more

When the electric pump is the only pump it’s usually best to use

a speed controller. This unit monitors coolant temperature as the engine warms

up, and varies the pump speed (and hence water flow rate) to suit the cooling

needs of the engine at that moment.

Pump Controllers - Read more (And the latest Davies Craig digital

pump controllers include the facility to switch the electric fan on and off as

well)

In some situations, for example in a race car, the pump can be wired to run permanently, turned on with the ignition switch, or a separate manual switch. Various options are possible!