Heat Soak Problems

Your

engine temperature is controlled via the cooling system with interplay between

heat produced, speed of water pump and engine cooling fan all controlled by a thermostat.

When the engine is switched OFF, the cooling system becomes inactive and the

residual heat in the engine from the block, head and exhaust manifold are

transferred to the coolant and other engine components.

If the

head is alloy and the block cast iron, heat soak is a particular problem as

they will expand at different rates, and there is a long term risk of head

warping, gasket damage etc.

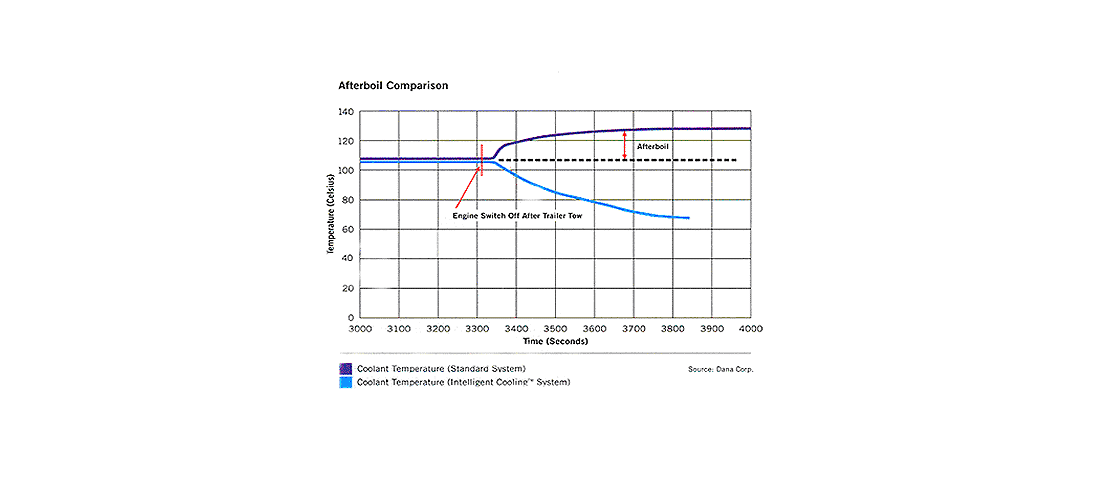

As the

graph shows, the typical effect of a conventional cooling system is that over a

long period the coolant is almost at boiling point until natural convection and

radiation eventually bring the engine and coolant system back to ambient.

For an

intelligent cooling system, an electric water pump and electric fan are

controlled by engine temperature irrespective of whether the engine is OFF or

ON. The effects of 'heat soak' are washed away in seconds as the cooling system

continues to do its job whilst the engine is OFF.

To

overcome damaging heat soak in your engine we recommend the combination of the

Davies Craig Thermatic fan, Electric Water Pump (EWP) and a EWP Dual

Controller.